The high-precision JIG compact series with a clamping surface

up to 1000 x 1500 mm

With MIKROMAT to productive µ

High demands ontechnical products of our time demand the highest precision.

Accuracy means productivity.

The MIKROMAT V series contains the traditional characteristics of the gauge drilling machines and the characteristics of modern precision bridges, which are constantly being further developed by a systematic designing the line of machines.

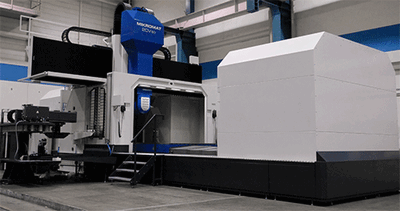

MIKROMAT 8V

The high-precision JIG compact series with a clamping surface

up to 1000 x 1500 mm

MIKROMAT 12V

JIG precision bridges for maximumaccuracy with a clamping surface

1250 x 2000 mm

MIKROMAT 20V

JIG precision bridges for maximum accuracy with a clamping surface

up to 2400 x 5000 mm

MIKROMAT 40V

JIG precision bridges for maximum accuracy with a clamping surface

up to 3800 x 8000 mm

Accuracy of the machine axes in combination with the highest manufacturing accuracy in terms of straightness and perpendicularity of the machine axes ensure the achievement of the highest volumetric accuracy in the entire working space. The patented wear compensation and the highest thermal stability thanksto controlled cooling processes simultaneously ensure the highest precision - for a lifetime!

A specially developedfully automatically interchangeable head system, including an option for jig grinding, makes it possible to meet the increased requirements in terms of precision and performance and upgrades the jig boring machine to a vertical/horizontal ultra-precision machining center. The variety of possible applications of MIKROMAT systems is evident in the systems for drilling and milling with table sizes from 800 x 1000 mm to 3800 x 8000 mm in a modular system, both for high-precision 5-side machining and for simultaneous 5-axis machining.