You are here: Mikromat GmbH > Products > Grinding

Profile and thread grinding of MIKROMAT

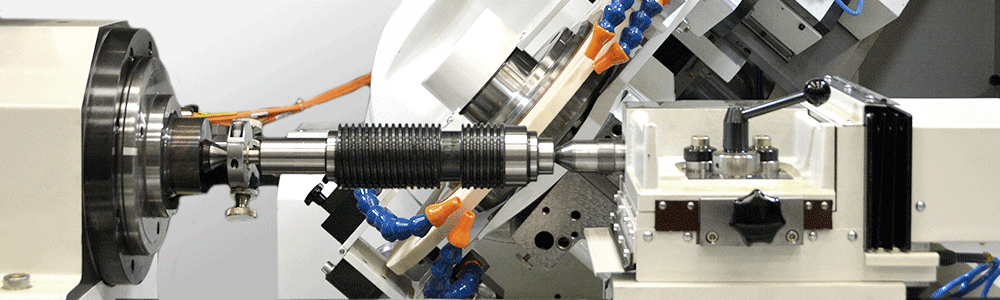

MIKROMAT thread grinding machines are designed for precision machining of workpieces with ambitious and highly different rotation profiles. Inside and outside contours can be grounded.

The CNC control developed at MIKROMAT guarantees precise interaction of all axes as well as safe and comfortable programming with workshop-oriented operator guidance directly on the machine, but also external. All movements required for grinding and dressing of grinding wheels are controlled and equipped with digital drives.

Areas with standardized profiles are lodged as a program module. Drive screw and adjusting spindles of various kinds, threading tools and plug gauges and many other workpieces are so effective to manufacture. But also special parts such as rollers for thread rolling, control wheels and transport drums for centerless grinding spindles for screw pumps or pinion for gear pumps can be generated and edited. Also for parts with cylindrical sections and flat surfaces as well as those in large series there are suitable solutions.

For profiling of grinding wheels - depending on the specific task - we use dresser with single point diamonds, forming rolls or profile rollers.We offer for the series production robots for loading and unloading of machines with appropriate magazines and measuring system for quality control.

The G-series of compact MIKROMAT includes machines for the production of very small and medium sized parts as well as machines with up to 3.000 mm grinding length.

|

Video B-Achse |  |

G-Series english (new) |

|

|

|

|